AI-powered visual inspection is revolutionizing manufacturing and quality control by delivering unmatched accuracy, speed, and intelligence to operational processes. By leveraging computer vision, machine learning, and artificial intelligence, these systems can automatically detect defects, anomalies, and quality issues that traditional inspections may overlook, setting a new global benchmark for operational excellence.

Contents In This Blog

What Is AI-Powered Visual Inspection

AI-powered visual inspection automates the detection of defects and anomalies by combining:

- Computer vision to interpret image and video data

- Machine learning algorithms to recognize complex patterns

- Artificial intelligence to adapt and improve over time

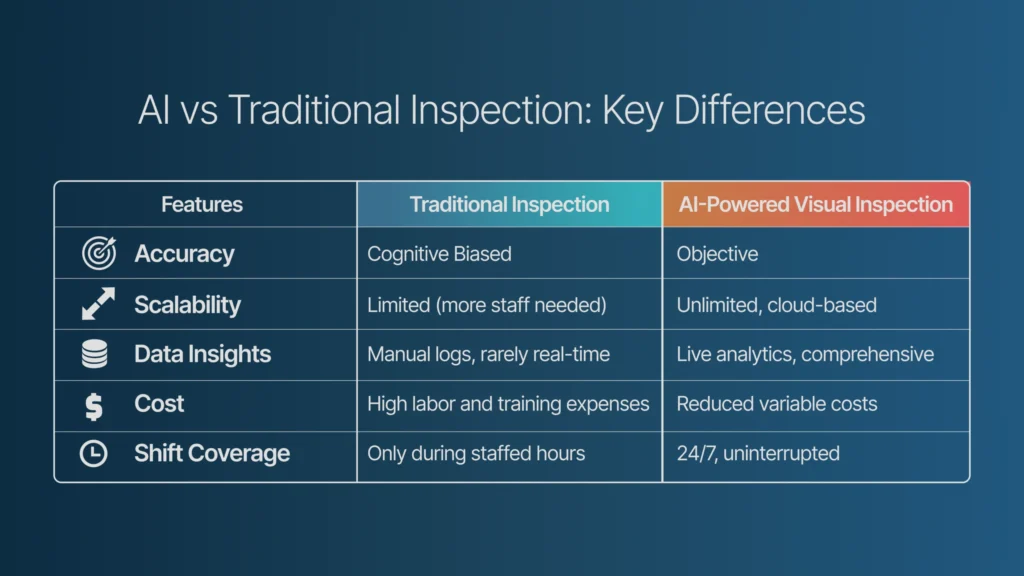

Unlike manual inspection that is subject to fatigue and inconsistency, AI systems operate continuously, adapting to diverse inspection requirements and enhancing efficiency across every industry, be it manufacturing, logistics, healthcare, or energy.

Streamlined Workflow of AI Visual Inspection Systems

- Visual Data Acquisition: Digital devices capture and transmit real-time data.

- Data Processing: Visual data is enhanced, cleaned, and structured for efficient AI analysis.

- Intelligent Analysis: AI algorithms rapidly analyze images and video to detect patterns, non-compliance, and inefficiencies.

- Auto Report Generation: The system auto-generates detailed reports for action.

- Continuous Learning: The platform improves with each inspection, learning from data and user feedback for ever-better results.

This approach transforms inspections from a reactive process to proactive, intelligent monitoring, reducing manual burden and preventing issues before they escalate.

Why Every Business Needs Automated Inspection

AI-powered visual inspection provides industry-wide advantages:

- Assured Compliance: Automated, standardized inspection ensures adherence to regulations simplifying audits and compliance.

- Reduced Costs: By eliminating manual inspection, companies minimize labor expenses, reduce costly rework, and prevent recalls.

- Remote Oversight: Real-time dashboards empower leaders to monitor sites from anywhere, improving coordination and transparency.

- Predictive Maintenance: Early warnings optimize maintenance schedules.

- Eliminates Human Error: Automated systems maintain peak performance 24/7, delivering consistent quality across all teams and shifts.

Embrace the Next Generation of Visual Inspection

Achieving operational excellence requires more than adopting new technology—it demands a proven solution and visionary partner. Detect Technologies’ T-Pulse platform stands out as a leader in AI-powered visual inspection, offering seamless, no-code integration and continuous performance improvement.

T-Pulse empowers organizations to:

- Eliminate defects and operational errors before they impact customers

- Achieve compliance with global standards effortlessly

- Track all inspection data for transparent, audit-ready records

- Unlock superior operational efficiency and cost savings

Want to see the difference?

Request a free demo of T-Pulse from Detect Technologies and take your first step toward defect-free, future-proof operations, empowering your teams to focus on innovation and deliver outstanding results.