Logistics Giant Leverages T-Pulse to Overhaul Workplace Safety at Their Largest Warehouse

Logistics is a complex and risky business. If the world were a single conscious entity, logistics would be its lifeblood. Moving goods and services around in a seamless manner is a formidable challenge and a profound reflection of the intricacies involved.

The process involves the transfer of goods through numerous hubs, warehouses, and distribution centers before they arrive at their destination. Warehouses are fraught with safety hazards at every turn. Persistent risks that threaten both goods and people include fires, falling objects, forklift accidents, slips, trips, falls, conveyor hazards, and vehicle collisions, among others.

Table of Contents

Overview of Client:

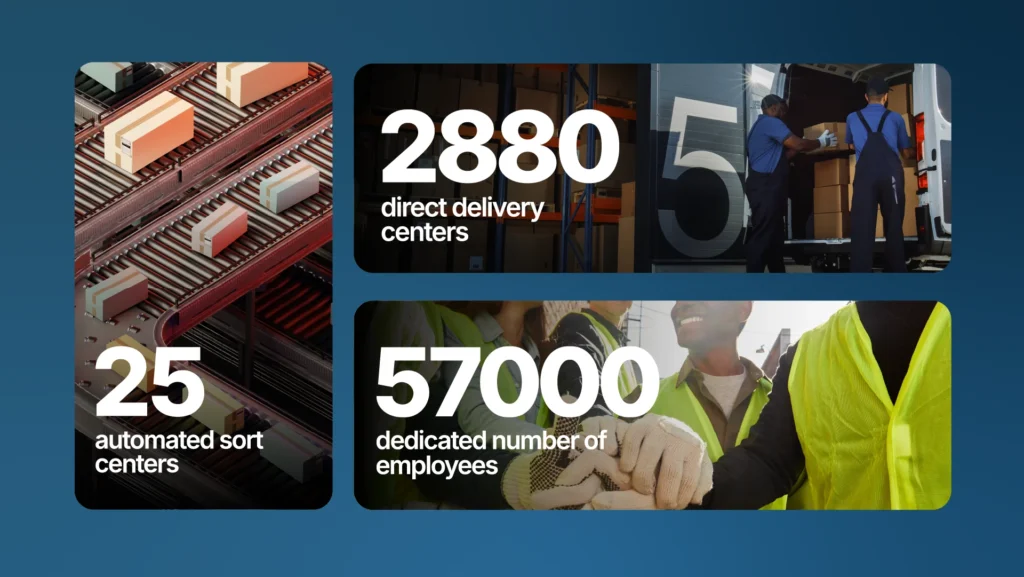

Our client, one of India’s largest fully integrated logistics providers, wanted to enhance the efficiency of their last-mile operations by reducing the risk of goods being damaged while being handled at the warehouse. To cater to this need they required a system that could intelligently pinpoint risks and integrate the insights into their centralized command center.

Challenges faced by the Logistics Operators:

The protracted challenges associated with last-mile logistics have perplexed industry experts owing to

High Volume and Complexity: The sheer volume, value, and handling complexity of goods make detailed, real-time monitoring difficult. High traffic and numerous hand-offs increase the chances of oversight.

Identification of risks: Without an intelligent surveillance system, identifying risks and assigning risk ratings proved challenging and costly.

Cross Performance and Coordination: Nodal centers lacked effective channels to escalate data-backed concerns, especially where risks were dynamic or continuously evolving.

Manual Reporting Processes: Outdated pen-and-paper-based reporting systems obscured the comprehensive visibility of risk management.

Embedding Intelligence for Last Mile Operations:

Given these challenges, the site required a highly flexible system that could be repositioned as needed to prioritize remedial action. A detailed survey was conducted, and it was decided to leverage the pre-existing infrastructure.

T-Pulse was implemented to monitor risks across key zones such as the Loading Bay, Dispatch Area, and Parking Area. AI algorithms initiated an audit analysis for the identification and categorization of key risk factors. All this data could be availed at a single point for review from the central operations center.

55% Decrease in Leading indicators

The advent of preliminary reports indicated that over 50% of observations were related to improper material handling and in-premise vehicle operations. As a result of these issues, the site was experiencing material damage and bottlenecks in achieving the targeted throughput.

Using T-Pulse the leading indicators for some of these most frequently occurring issues were identified and monitored closely. Over the period, T-Pulse armed the management with more than 9000 actionable insights covering the root causes with unprecedented granularity.

The data from T-Pulse unveiled that 90% of the overall risk at the site could be categorized under the following 5 risk profiles: improper material handling, hazards associated with movement of vehicles, line of fire hazards, people in unsafe positions, and unsafe access zones.

With this information, the site was able to refresh its change management program to ensure a greater emphasis and resource allocation towards the mitigation of these hazards, leading to a 55% improvement in the risk profile. The client was able to promptly address the workplace design and human aspects of warehouse safety while strengthening participation across the group to identify and adopt better ways of working.

With T-Pulse improvement is a daily opportunity as it tirelessly monitors the risks for the designated areas, enabling the safety personnel to focus their attention on more demanding tasks.