Oil and Gas Conglomerate Leverages T-Pulse for Effective Risk Management Across Diversified Upstream Installations

A prominent oil and gas conglomerate, facing challenges in coordinating safety protocols and ensuring regulatory compliance across its diverse upstream operations, turned to Detect Technologies for a transformative solution. By implementing T-Pulse, an innovative AI-powered platform, the client achieved unparalleled visibility into its bifurcated offshore and onshore installations.

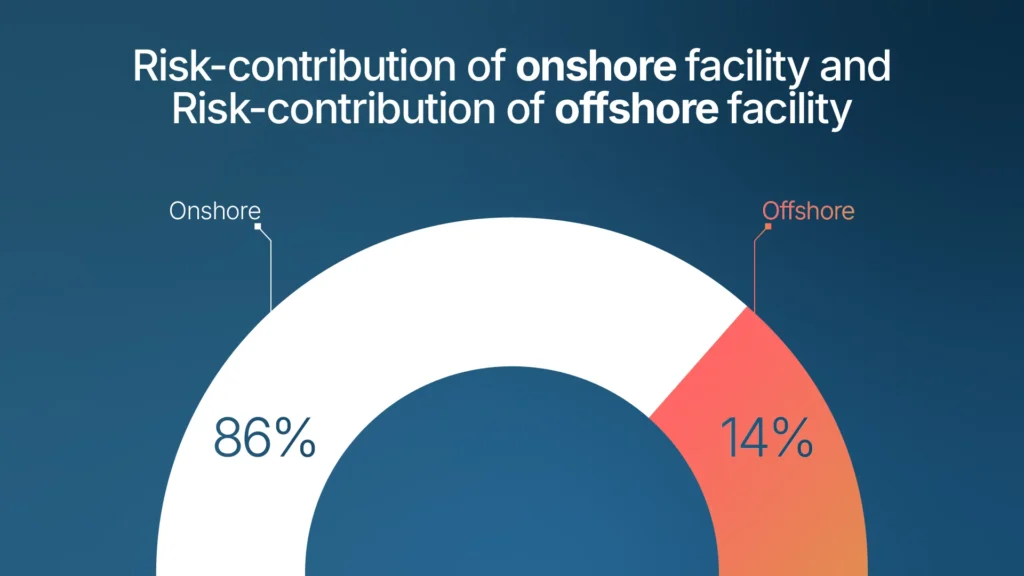

Within the first quarter of deployment, T-Pulse revealed a critical insight stating that a mere 14% of risks originated from offshore facilities, while a staggering 86% stemmed from onshore operations. These granular insights empowered the client’s safety team to develop targeted mitigation strategies tailored to the specific risks prevalent in each environment.

Upstream worksites like oil rigs and pump jacks play a vital role in our daily lives by extracting crude oil that our society consumes in various forms. But you will be surprised to realize that these perpetually engaged, and economically essential installations also happen to be the most dangerous places to work. Consistently among OSHA’s deadliest 3, upstream worksites often face delays, disruptions, and prolongations due to many safety-related incidents. Often these incidents result in injuries and fatalities ultimately decreasing workers’ quality of life.

Studies assessing the impact of safety incidents in the oil and gas (upstream) industry have estimated the average cost of a single lost time injury to be around $155,000. This includes both the direct costs (medical expenses, workers’ compensation claims, legal fees, etc.) and indirect costs (lost productivity, fines, reputational damage, etc.).

Upstream operations differ significantly from traditional process industries, mostly due to the remoteness of location and geographical challenges. Also, upstream worksites are bifurcated installations – unlike singular units, they consist of separate offshore and onshore facilities, each specialized to support different activities associated with extraction. The offshore facilities handle exploration, extraction, support, and initial processing of petroleum, whereas the onshore facilities take care of secondary processing, storage, and administrative functions.

Despite its many operational benefits, this division also introduces certain coordination and communication-related challenges, complicating safety and emergency response efforts.

Summary

Overview

Our client was facing difficulties managing both onshore and offshore aspects of their upstream operations. The fragmentation made it difficult for the onsite safety management crew to get a unified view of all the risks. Coordinating safety protocols, ensuring regulatory compliance, and integrating risk management at a remote location with bifurcated installations was complicated and demanding.

Effective management required a robust strategy to ensure seamless operations and comprehensive risk assessment coordinated across both offshore and onshore installations. A thorough risk assessment was essential for identifying and categorizing potential hazards based on their severity and likelihood, highlighting high-severity and high-likelihood risks that could cause significant disruptions or harm. To add to the trouble, the client lacked sufficient data for decisive pinpointing and effective resolution of safety bottlenecks.

Challenges Faced by the Client

- Low and dissipated information density.

- Lack of coordination between onshore and offshore units of the upstream extraction plant.

- Lack of sufficient data to properly formulate a risk addressal policy.

- Lack of a system to efficiently record, segment, store and retrieve data.

- Inability to detect lack of compliance with established safety standards.

Detect Technologies Steps In

The client engaged Detect Technologies to help overcome the massive challenge and we took it upon ourselves to enable and implement technologies for safeguarding assets, workforce, and operations. Our engineers initiated the process of evaluating their requirements and tailoring our award-winning AI solution T-Pulse to meet the needs.

T-Pulse harnesses advanced AI technology and existing cameras and sensors to create an intelligent vision-based compliance monitoring ecosystem for risk management at industrial workplaces. An intelligent system already familiar with high-risk environments like drilling stations, rigs, pumping stations, FPSOs, etc., T-Pulse provided the management with a comprehensive view of different work conditions and provided actionable insights to help resolve safety risks.

T-Pulse started collecting, processing, and consolidating data from the bifurcated facilities, enabling effective monitoring of key risk indicators. This data was then centralized within a command center for coordinated risk monitoring and response planning, thereby enabling a comprehensive and proactive risk management strategy across both the upstream work fronts.

Results Achieved

T-Pulse enabled a systematic approach to risk assessment, facilitating comprehensive coverage, better coordination, and preemptive resolution of incidents. It helped the client retain crucial data which helped identify leading indicators of compromise that precede high severity high likelihood scenarios.

Having addressed this gap, the client could now implement systems focused not just on consequences but on root causes as well, all the while monitoring improvements in their risk management framework.

Within the first quarter of implementation, T-Pulse was instrumental in identifying that only 14% of the risks originated from offshore installations while onshore installations were responsible for the remaining 86%. Insights delivered to the client’s safety management team helped them better assimilate mitigation techniques for both scenarios.

For instance, they learned that in offshore installations, line of fire hazards, object strikes, slips, trips, and falls were common while the onshore installations were more exposed to risks from lifting and hoisting, storage, vehicle movement, machinery, leaks, spills, and security-related events.

Based on these granular insights delivered by T-Pulse, the client was able to better focus their efforts, reposition their strategy, and prioritize their investments to tackle their workplace risks more effectively.

Conclusion

The deployment of T-Pulse empowered the client, enabling them to enhance workplace safety and cross-site collaboration. By leveraging AI technology, the client achieved unparalleled visibility into their operations, drove continuous improvement, and made smart investments where they were most needed.

The key to better workplace safety lies in improving visibility and coordination across worksites. A daunting task by contemporary standards, the same can be achieved with relative ease today by harnessing the power of generated data through AI, ML, cloud computing, IoT, and other similar new-age technologies.

To learn more about how you can ensure optimal resource allocation and improve emergency response times at your industrial workplace, consider going through this blog that discusses the role of visual AI in detail.

To start building an intelligent safety ecosystem at your workplace with T-Pulse, get in touch with our industry-leading experts today.