Protecting Industrial Pipeline Networks against Corrosion Failures with GUMPS and T-Pulse Maintenance Assistant

Corrosion-related failures are common in industrial sectors that involve extensive fluid storage and processing. Unmonitored and unchecked corrosion can lead to costly downtime and safety incidents, raising serious monetary and environmental concerns. It can compromise the integrity of critical infrastructure like pipelines, pressure vessels, and storage tanks, leading to catastrophic outcomes for the workplace and surrounding areas.

The financial costs associated with corrosion-related asset failures extend beyond direct repair and replacement costs to include penalties, lost opportunities, and reputational losses. Preventive corrosion monitoring and management, therefore, is essential to ensure the safe, reliable, and efficient operation of assets in these industries.

Summary

Client Overview

Our client, one of the world’s largest oil and gas companies, operates in all areas of the energy sector, including oil and gas exploration, production, refining, distribution, and marketing. The company is also a significant player in the renewable energy market, investing in wind, solar, and biofuels as part of its strategy to transition towards a lower-carbon future.

The client was struggling with corrosion loop management at one of their largest refineries in the APAC region. An organization strongly committed to sustainability and innovation, they were looking for a safe, cost-effective, and reliable method to predictively address corrosion-related hazards. Using existing “reactive and sporadic” thickness-based preventive maintenance methods, the client was fighting an uphill battle against corrosion, facing challenges like:

Access Difficulties: With corrosion-prone areas being hard to access, regular inspection and monitoring were challenging.

Complicated Corrosion Dynamics: Understanding the diverse and complex mechanism of how corrosion forms, spreads, and evolves in different environments and materials was challenging.

Lack of Data Sufficiency: Traditional inspection methods provided discrete and incomplete data points, leading to a lack of insights and therefore unanticipated failures.

Uneven Resource Allocation: The unavailability of proper data to be processed into comprehensive insights inhibited a proper allocation of resources to the most critical areas leading to inefficient resolutions.

Process Variability: Fluctuations or changes in the operating conditions of a pipeline network like variations in feedstock composition, temperature, pressure, flow rates, and chemical exposure had a significant impact on corrosion rates and mechanisms.

Integrating T-Pulse and GUMPS

Wall thickness is traditionally used as the key indicator for assessing corrosion in piping systems. Under this approach, thickness inspections are carried out using a grid-based method. However, due to limited data availability, subsequent inspections are often scheduled based on the results of the previous inspections, with maintenance planning relying on assumptions about the annual thickness reduction rate.

Additionally, the traditional methods of pipeline inspection are also wrought with safety bottlenecks, further complicating accurate thickness measurement.

“In addition to the constraints referenced above, the primary drawback of conventional inspection methods is an assumption that the point of failure will remain constant over time. Without detailed and continuous data, however, it is impossible to precisely pinpoint monitoring locations for detailed inspections.”

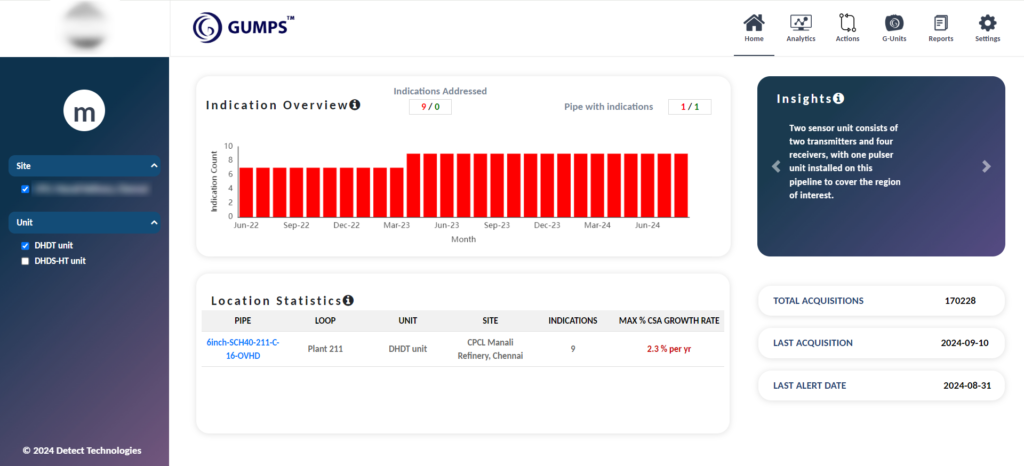

GUMPS is an IoT-based system that helps monitor pipeline corrosion dynamics and metal loss in real time. Unlike traditional sensors that provide only point-based readings, GUMPS can continuously monitor entire sections of the pipeline, offering detailed health data. This data is then processed by T-Pulse (the most trusted AI-powered data analysis engine across industries) to reveal indications of deterioration like percentage cross-sectional area loss (%CSA loss) and annual corrosion growth/proliferation rate. Once documented, T-Pulse generates detailed corrosion metrics and provides actionable insights to engineers on how, where, and when to plan detailed inspection activities.

Results Achieved

By leveraging data from GUMPS and insights from T-Pulse, the client was able to effortlessly identify numerous areas experiencing metal loss. The system unveiled further insights into these points of vulnerability:

- 18 different areas of imminent leakage, where metal loss had exceeded 14% were identified and highlighted across the entire pipeline network

- About 67% of these areas didn’t align with historical data and could not have been detected using conventional inspection techniques.

- The automated and continuous monitoring capability provided insights into the perfect timing for conducting detailed inspections.

Better insights enabled the client to make proactive decisions while bringing efficiency to their inspection planning. The combined impact led to significant savings in inspections and clean-up costs.

Thanks to its non-destructive, intricate, and meticulous examination of piping networks, GUMPS powered by T-Pulse provided visibility into vulnerable areas. Through sustained usage of the system, the client was able to double the life of their corrosion-prone assets in addition to realizing benefits like:

Optimal Resource Investment: Thanks to state-of-the-art predictive maintenance, inspections can be appropriately planned when indication levels approach the design threshold, negating unnecessary disturbances and premature downtime.

Enhanced Inspection Precision: Inspection precision is increased with a focus on critical indication levels, enabling a targeted approach to pipeline health monitoring.

Streamlined Data Management: GUMPS collects and maintains detailed data on various indications across pipeline segments, simplifying decision-making with comprehensive insights.

Improved Visibility and Reporting: GUMPS provides clear visibility into pipeline health through detailed reports, including indication tables and pipe isometry.

Conclusion

Implementation of GUMPS with T-Pulse revolutionized pipeline inspection and monitoring at the client’s facility, offering a precise, data-driven, and efficient approach to managing pipeline integrity. By shifting from traditional, schedule-based inspections to a dynamic system that responds to real-time data, the client was able to enhance the accuracy of their inspections and reduce the frequency of unnecessary checks, saving time and resources.

If you’re looking to elevate your pipeline monitoring strategy to the next level and improve the safety and reliability of your operations, GUMPS is the solution you need. Witness the transformation with your own eyes! Sign up for a demo today, and proactively safeguard your infrastructure with GUMPS.

Intrigued by the solution? What do you think can be the other applications of GUMPS with T-Pulse? Let us know by filling up the form below: